SMC Service Highlights:

Customized Solutions

Tailor-made fixture, jig, and socket designs to precisely meet your product and process requirements.

High-Precision Design

Utilizing advanced EDA simulation tools and precision manufacturing technologies to deliver durable, high-accuracy components that meet the highest quality standards.

Reliable Performance

Our designs are engineered for consistency and long-term use in demanding production and testing environments.

Comprehensive Support

From concept to delivery, our experienced team ensures full-cycle support and seamless integration into your production line.

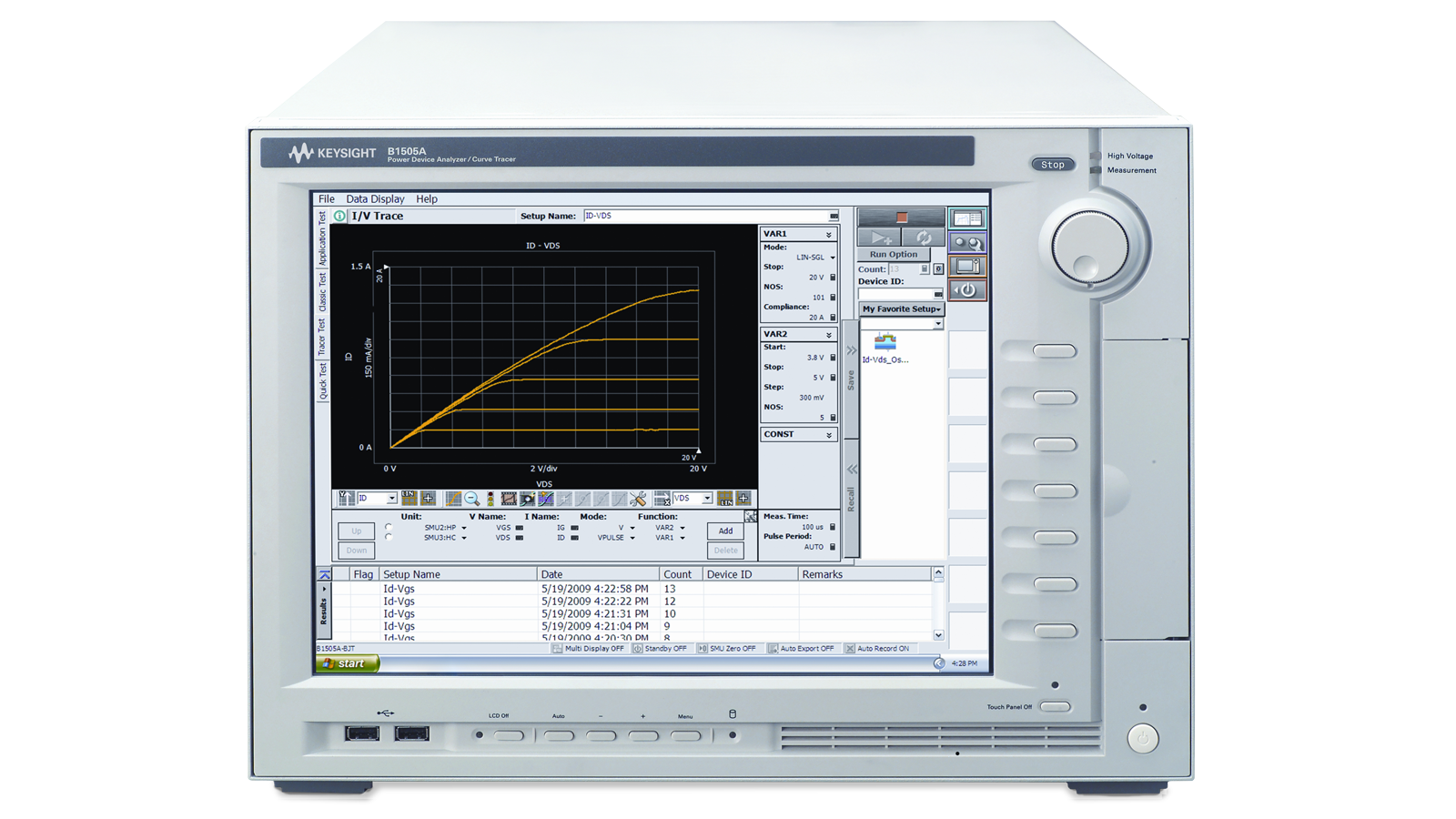

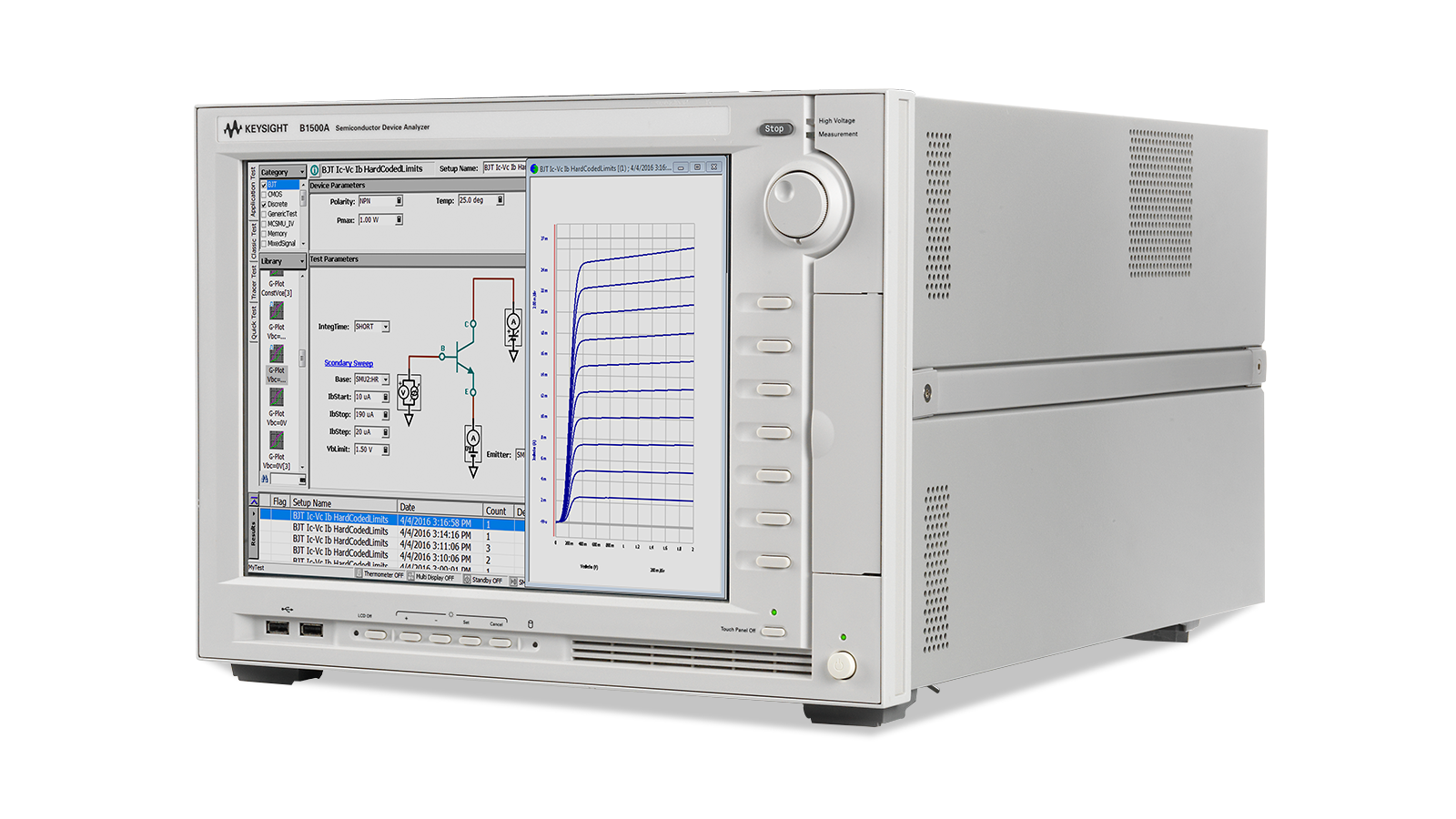

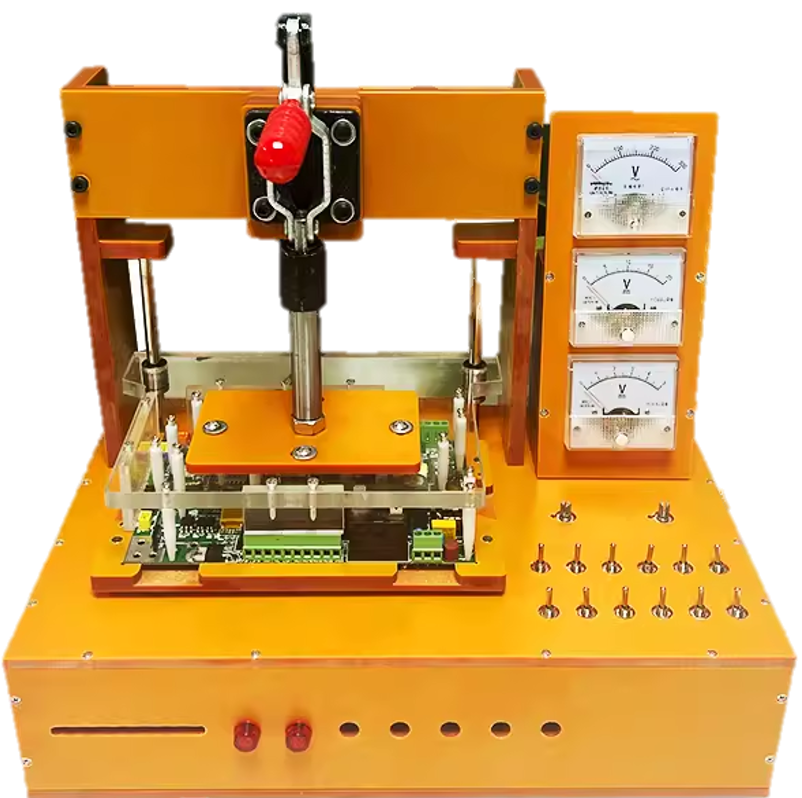

Test Fixture : A mechanical fixture used during hardware testing to securely hold the test sample in place and maintain consistent testing conditions. For example, fixtures for PCB testing provide stable connections between the DUT (Device Under Test) and test instrumentation to ensure accurate and repeatable measurements.

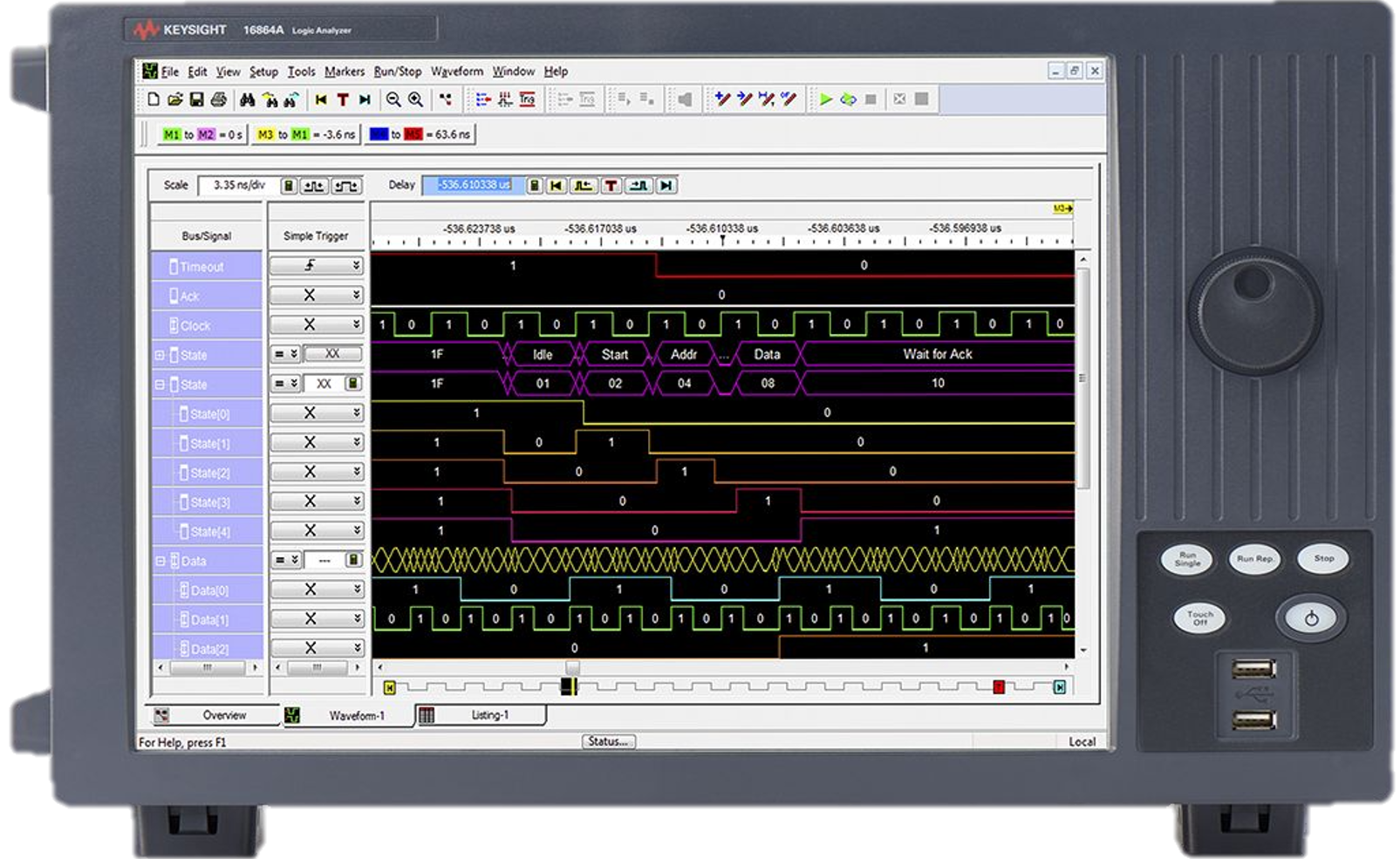

Test JIG:A custom-designed tool for testing electronic components or PCBs, ensuring consistency and precision during the test process. Jigs enable fast, efficient, and repeatable batch testing, improving productivity and reducing manual handling errors.

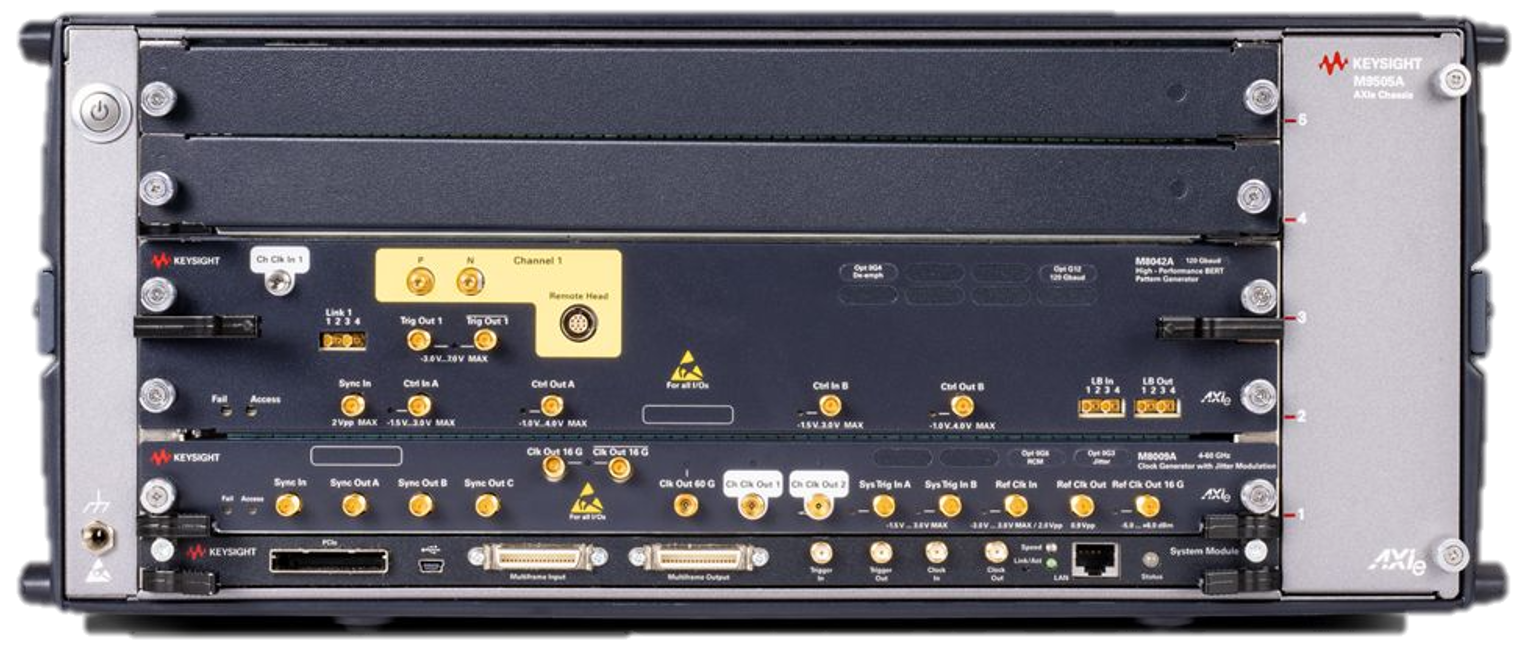

Test Socket:A precision interface tool used to perform functional, performance, and reliability testing on semiconductor devices or modules. These sockets ensure safe, reliable electrical connections with the DUT, enabling stable contact and highly accurate test results.

Fixture

JIG

Socket